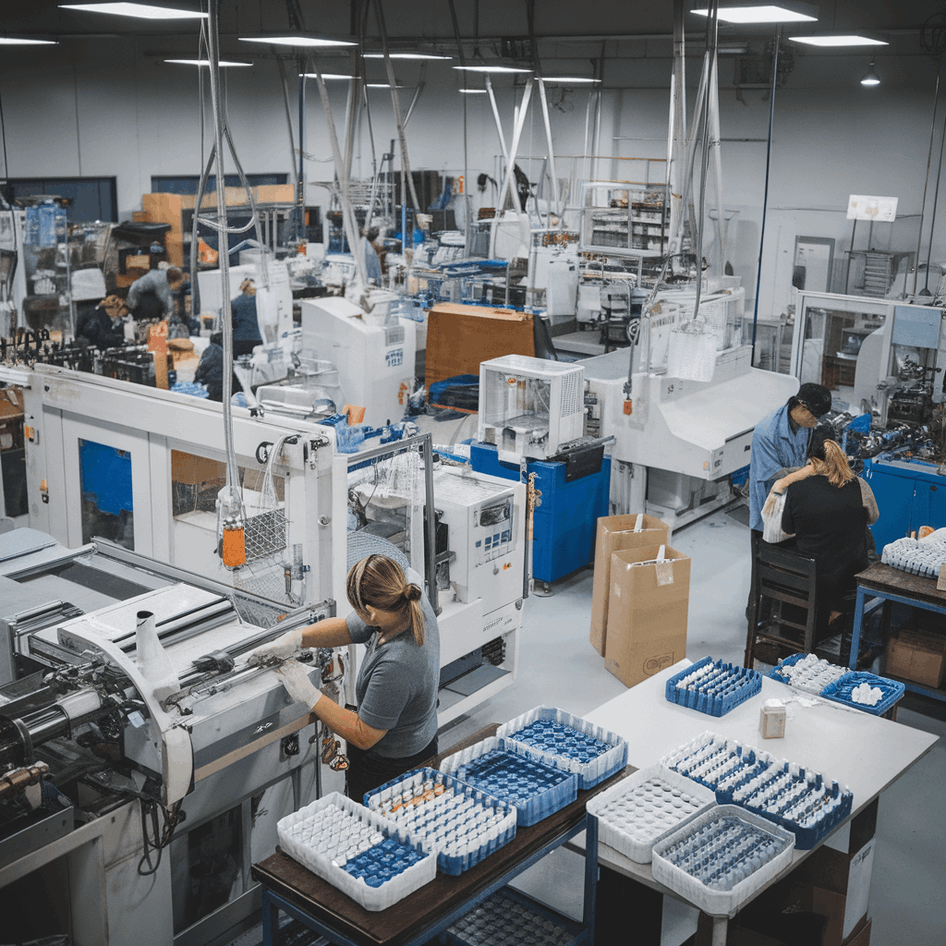

We manufacture high-volume plastic holders, cases, and accessories for medical and diagnostics brands. Cleanroom molding, serialized traceability, and fast, robust tooling — all from Shah Alam, Malaysia.

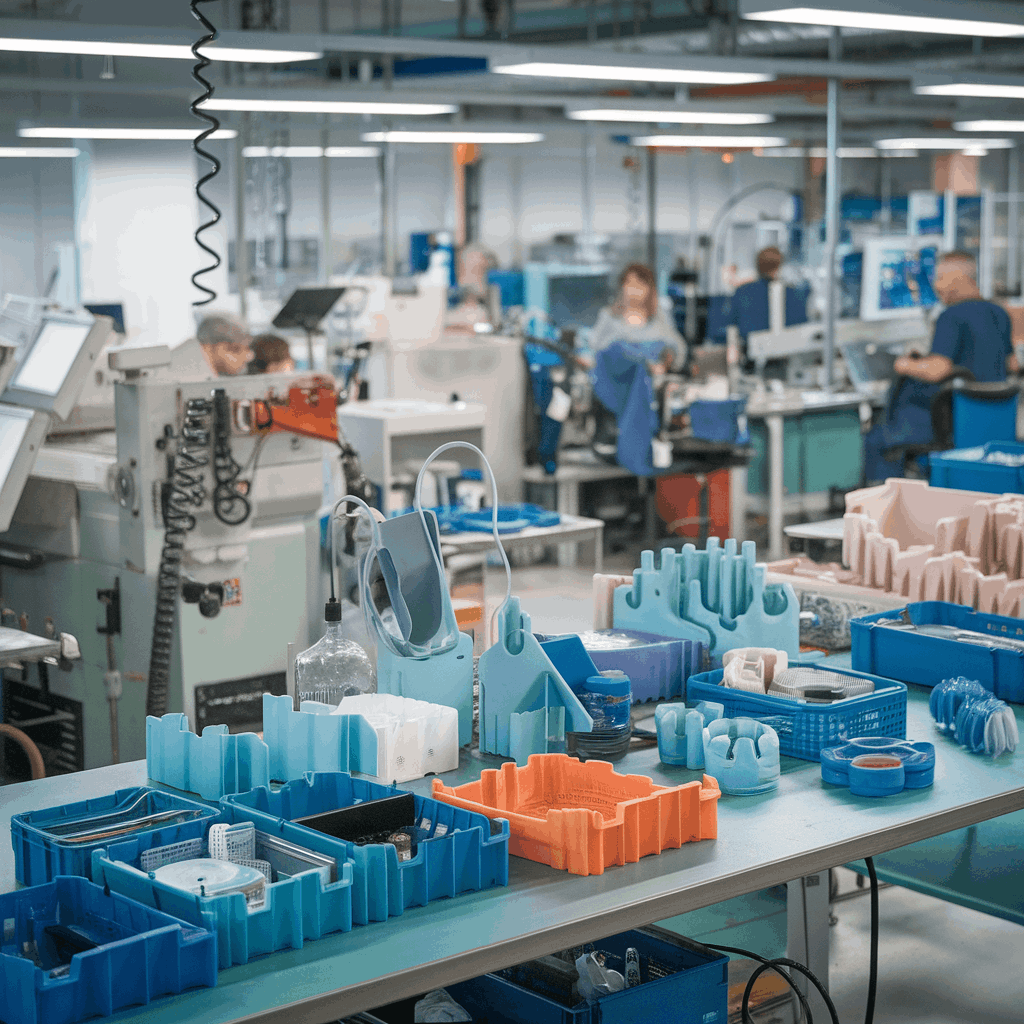

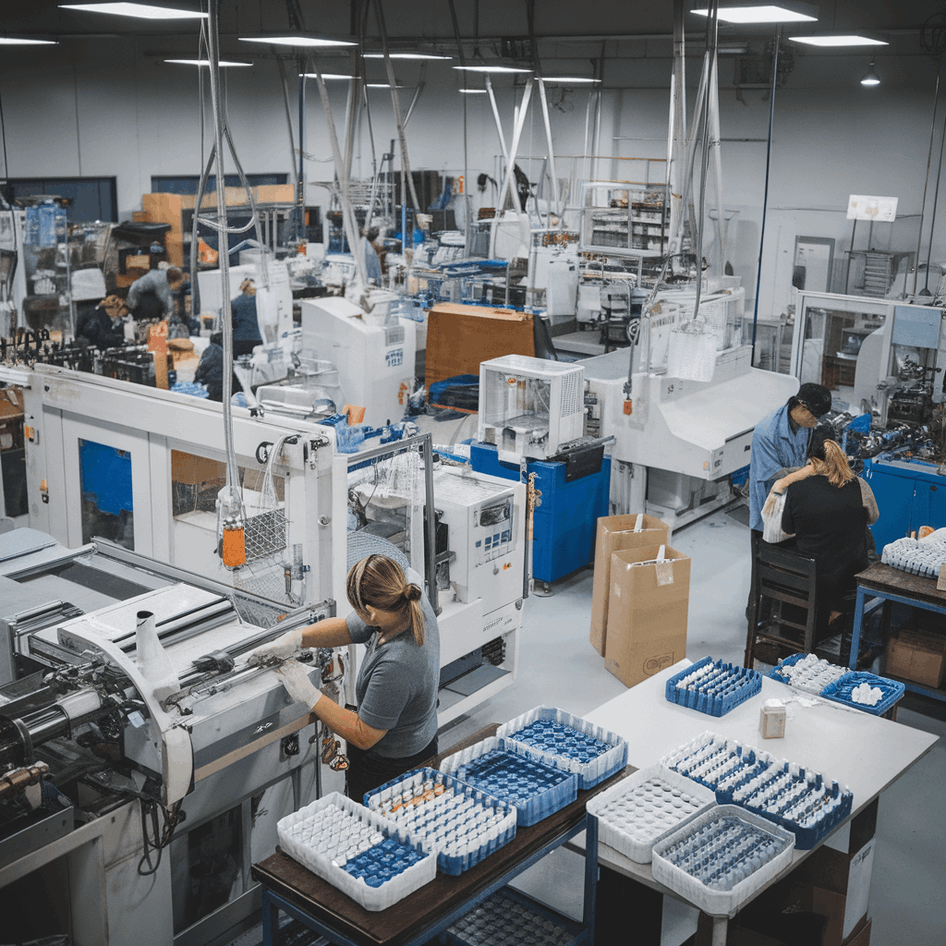

We combine validated molding cells with dedicated secondary processes for clean, repeatable parts.

Founded by process engineers and quality specialists, PercepJBLN focuses on disposable medical plastic products that require consistency above all else.

Our facility in Shah Alam is designed for lean flow and rapid changeover between validated SKUs. We maintain robust incoming inspection, SPC on critical-to-quality dimensions, and full lot traceability.

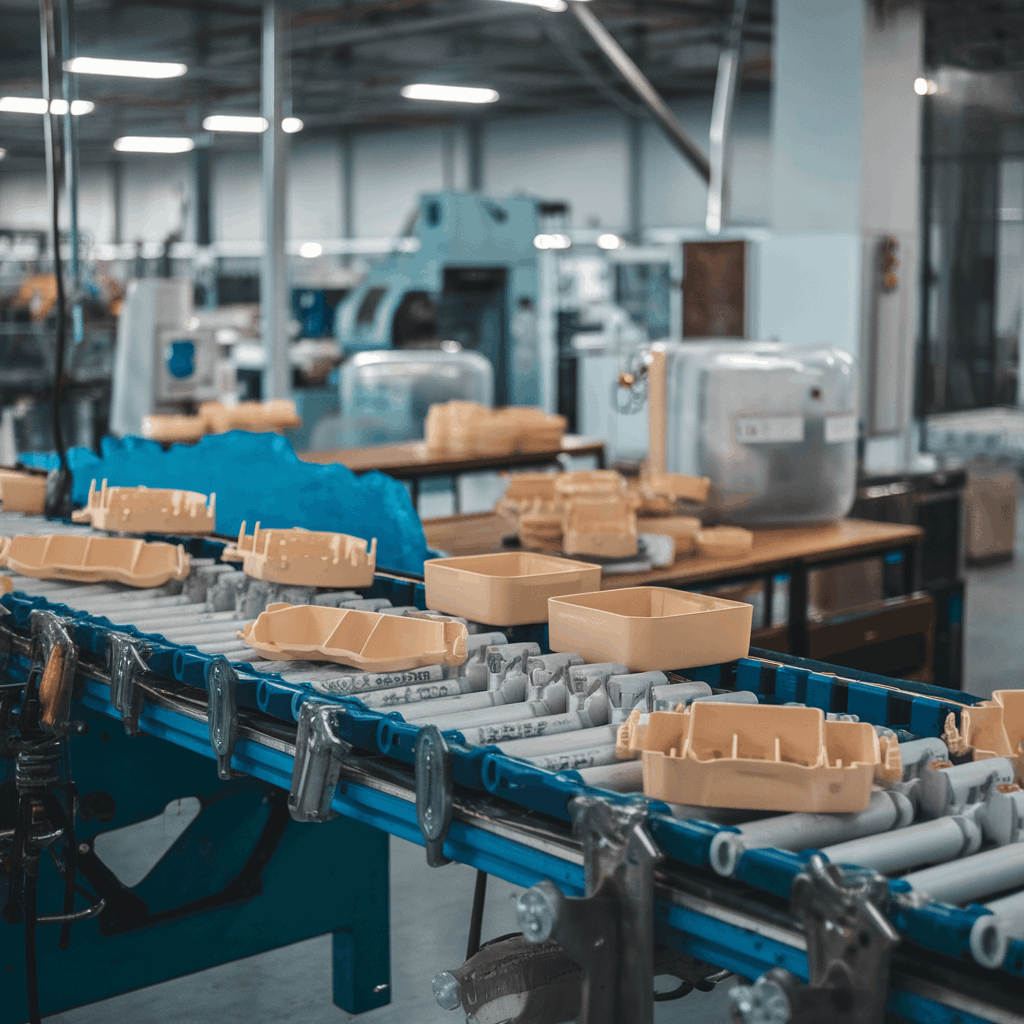

Medical plastic holders, cases, and accessories engineered for workflow, ergonomics, and cost-per-use performance.

For rapid test cassettes and microtubes; anti-tip design with textured grips.

Impact-resistant shells for kits and field diagnostics with secure closures.

Clips, caps, and mounting parts designed for repetitive handling with low burr risk.

Preventive mold care schedules and cavity-level measurement records to sustain capability.

Vision checks for cosmetic defects and dimensional sampling with SPC dashboards.

Cells balanced for steady takt times and quick scale-out as demand grows.

From design-for-manufacture to pack-out, we build reliable processes for medical disposables.

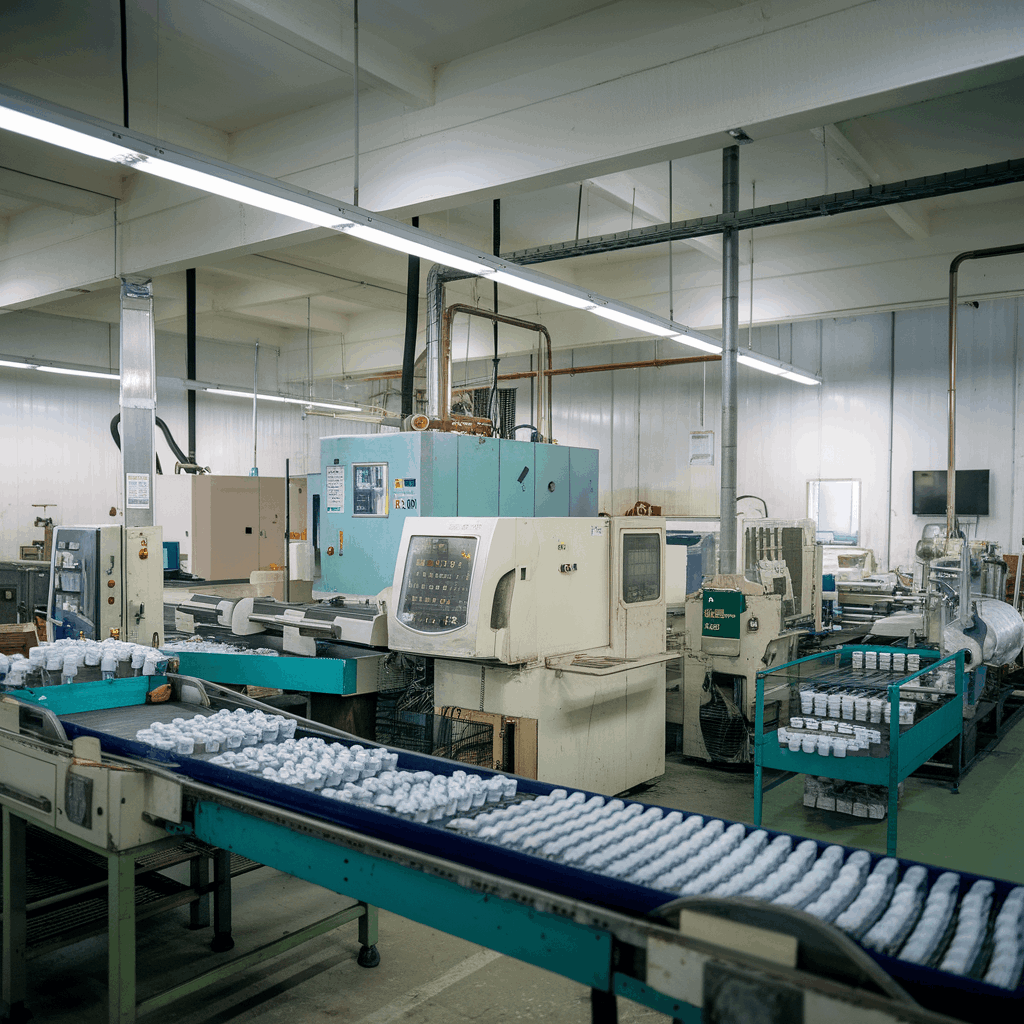

Multi-cavity tooling with hot runners and cavity pressure monitoring. Gate and weld line controls aligned to CTQs.

White room and ISO-class areas for assembly, kitting, and label application with barcode verification.

Local tool room partners and documented maintenance cycles reduce unplanned downtime.

“We only ship parts we’d be proud to assemble ourselves.” — Production Lead, PercepJBLN

We align to international standards for medical-adjacent plastics, maintaining verifiable records at each step.

External reference: Malaysia’s medical device ecosystem overview on MIDA.

By adjusting gate positions and refining cooling, we cut warpage by 64% and improved stack fit, raising first-pass yield to 98.2%.

For a new accessories kit, we validated tooling and packaging in parallel, hitting SOP within six weeks and meeting APAC launch targets.

See our latest updates on LinkedIn.

Components for point-of-care and lab workflows with ergonomic handling.

Protective cases and mounts optimized for low total cost of ownership.

Accessories for sample prep, storage, and transport with clean interfaces.

“Their response time on tooling and quality reports is exceptional. We scaled volumes without surprises.” — Procurement Manager, Diagnostics OEM

“PercepJBLN helped us rework our holder design for better stacking. The results cut our logistics damage rate significantly.” — Ops Director, Medical Kits

Tell us about your part, resin, and volumes. We’ll propose a robust manufacturing plan.

PercepJBLN Manufacturing Sdn Bhd

Lot 9, Jalan Utarid U5/16, Hicom Industrial Estate

40150 Shah Alam, Selangor, Malaysia

Phone: +60 3-7841 9302

Email: contact@percepjbln.org

Mon–Fri, 8:30am–6:00pm (MYT)